Tesla CEO Elon Musk says chip shortages are limiting vehicle and robot production, proposes building massive in-house semiconductor factories.

Elon Musk announced plans to build an enormous semiconductor manufacturing facility, aiming to secure the chips needed for Tesla’s ambitious electric vehicle and robotics projects.

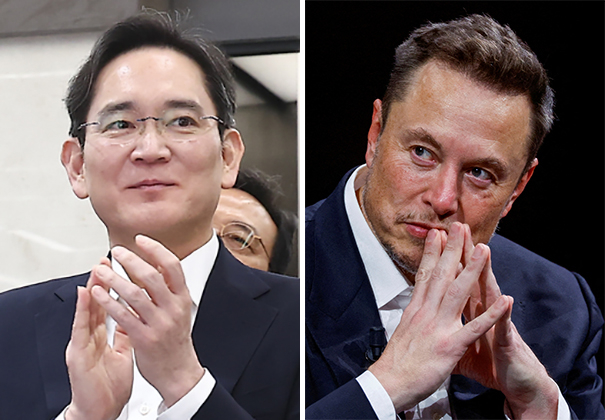

Speaking at Tesla’s annual shareholders meeting on Thursday November 6, 2025, Musk described chip availability as a “limiting factor” for the company’s next-generation vehicles, including the driverless Cybercab, and the Optimus humanoid robot. Despite buying all available chips from major contract manufacturers like TSMC and Samsung, Musk said current supply cannot meet Tesla’s growing demand.

“As far as I can see, the only option is to go build some very big chip fab,” Musk said, adding that memory and packaging challenges would also need to be addressed. He dubbed the proposed factory the Tesla Terra Fab. The facility would aim for at least 100,000 wafer starts per month—roughly five times the output of TSMC’s first Arizona fab—and could eventually scale to ten such fabs, producing a total of one million wafers monthly.

Each wafer could yield dozens or even hundreds of chips, depending on the design. Among the planned chips is the AI5 processor for new Tesla vehicles, which Musk says consumes roughly a third of the power of an Nvidia Blackwell GPU while delivering comparable performance.

Read Also: Elon Musk Warns “Artificial Intelligence” Will Rule Humanity

Building the fab—or the envisioned complex of ten fabs—would take years, require highly specialized chip engineers, and demand investment exceeding $100 billion. Musk did not provide a specific timeline but mentioned potential short-term discussions with Intel about utilizing existing manufacturing capacity.

The announcement comes shortly after Tesla shareholders approved a $1 trillion pay package for Musk, a sum far larger than the estimated cost of his proposed chip venture. Analysts said the move signals Tesla’s intent to vertically integrate further and reduce dependence on external chip suppliers, a strategy increasingly pursued by automakers and tech firms amid global semiconductor shortages.

Musk’s plans underscore the broader challenges facing the semiconductor industry, where rising demand for AI, electric vehicles, and robotics continues to outpace production. By building its own massive fabs, Tesla could gain strategic control over supply, potentially accelerating production of next-generation vehicles and autonomous systems while easing pressure from the global chip shortage.

Tesla did not immediately respond to a request for comment regarding the project’s timeline or funding sources.